Medical

TOP® focuses on the field of precision manufacturing, providing customers with flexible and efficient smart manufacturing solutions, and its business covers many component of Medical industries.

● Ventilator parts

● Surgical instruments components

● Orthopedic medical devices component

● Custom tooling brackets and chassis for medical manufacturing

● Rapid prototyping of medical devices using CNC machining

● Custom fixturing, fittings

● Personal protective equipment (PPE)

Case of CNC machining for medical used

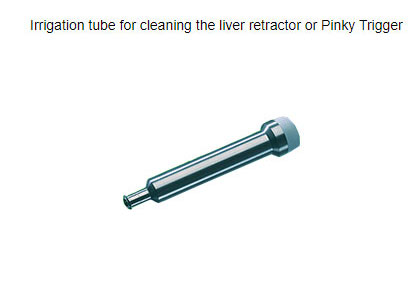

Pinky Trigger

The Pinky Trigger is a reusable 5mm laparoscopic instrument that can be used both as an insertion aid for gastric bands and as a bilateral dissector.

Challenges

This project is Pinky Trigger. It's surgeon’s finger use for dissection. It's a dynamic device, which allows for back and forth movement of the tip by pulling the lower handle at the hand piece, the parts request a very tight tolerance and all the parts need in a good fit. Also the production have to be done in 30 days for big quantities..

Our team’s expertise allowed us to pinpoint the optimal approach to the project in accordance with practices. We also thoroughly vet all of our third-party vendors long before any project outset including raw material and treatment process. Our trusted partners had a good suport with us.

Unique Solution

We employ a unique approach to the manufacturing process and deal with the samples in 6 days. All of our material full traceability on allowing our clients to quickly and easily determine the source and quality of their products. Traceability

is important for a medical device, it's key to ensuring optimal functionality and patient safety.

Project Outcome

During the process , we perform double quality check for full production to ensure manufacturing quality. Our efficient production and super quality was satisfied by customers. The client has ordered additional production runs for the same part multiple times since.

Our custom CNC machining was trusted by many of our customer inf the fild of medical,

✔ Medical device manufacturers

✔ Healthcare providers

✔ Life sciences

✔ Biotechnology corporations

✔ Pharmaceutical companies

✔ Diagnostics equipment manufacturers

✔ Surgical and medical instrument manufacturers

✔ Surgical appliance manufacturers and suppliers

✔ Hospital operators

Example parts for Medical used

CNC machining in the pharmaceutical industry

High-quality pharmaceutical equipment is a necessity in the modern medical industry. The materials commonly used by manufacturers of orthopedic instruments, surgical instruments and implants are titanium, stainless steel Invar, Kovar and Inconel.

Some of our CNC machining parts can be used in pharmaceutical companies, including

● Centrifuge

● Cooling Tower

● Dryer

● Granulator

● Capsule equipment

● Coating machine

● Testing Equipme

What is a centrifuge?

CNC machining centrifuge

Centrifuges are commonly used laboratory equipment in the pharmaceutical industry to separate fluids, gases or liquids based on their density. Rotating the container at high speed allows centrifugal force to push the heavier material out of the container.

Some of the most common types of centrifuges used by pharmaceutical companies including,

● Desktop

● Refrigerated desktop

● Clinical benchtop

● Microcentrifuge

● Concentrator

Our well-trained professionals will work with you from start to finish, and even complete the most unlikely processing goals. We demonstrate this through a commitment to efficient production and customer satisfaction.

Contact us, our custom design and production services will be benefit to your next project.