CNC machining

We are focused on helping you bring your products to market as quickly as possible.

What is CNC and CNC Machining?

“CNC Machine” is typically used to refer to a device which uses a rotating cutting tool which moves in 3 or more axes (X, Y and Z) to cut-out or carve parts in different types of materials.

like the image showswith labels for some of the key components and also an indicator showing the 3 axis of movement (X, Y and Z) and their directions in relation to this particular machine.

CNC(Computer Numerical Control) is a kind of subtractive manufacturing. Based on the drawing, CNC uses different tools to cut the raw material by programming.d their directions in relation to this particular machine.

Advantages of CNC machining

Many manufacturers prefer machining processes because they create parts or components from a single workpiece. CNC machining also has additional advantages including,

●Increased productivity

Facilities with CNC machining can produce parts 24h. The machines may run continuously with little-to-no human intervention.

●High degree of accuracy.

CNC machining uses highly detailed programming operations. The machines follow these instructions without any unwanted variation or human error. The parts will be high-quality, precise, and identical. CNC machining can also produce parts with intricate, complex designs.

●Faster project completion

Every CNC machining process starts with a CAD design, the software catches or prevents many possible design flaws or potential risks with different materials. In this way, the prototyping and testing processes are shortened, products can go from design into production faster. CNC machining instructions can also be modified or replaced quickly, so there is little delay between changes in production runs.

●Cost-effectiveness

CAD file designs and reduced risks of manufacturing errors reduce the per-unit cost of production. CNC machining also requires less human labor, which further reduces the price of manufacturing the products.

How to decide 3/4/5 axis CNC Machining for my part?

The “axis” means the available sides can be machined. 5-axis indicates that the cutting tools work along XYZ+AB sides. The complex part requires higher “axis” machining. Our engineers will advise the suitable machining way for you according to your budget, material, and finishes.

CNC Machining capacitie | |

Process | CNC turning, milling, drilling, auto lathe, tapping, bushing, surface treatment |

Material available | Aluminum,Brass,Copper,Bronze. |

Stainless steel,Steel,Galvanized sheet. | |

Plastic(ABS,POM,PC,PMMA,Nylon,PEEK,PTFE, etc.) | |

Dimension | Customized |

Surface treatment | Sandblasting/Anodized/Polishing/Brushing/Plating/Oxidizing/Powder Coating etc. |

Tolerance | 0.01~0.005mm, depenons on drawing |

Equipment | 3-axis,4-axis, 5-axis, CNC machining center, CNC lathe, milling,grinding, wire-cutting, laser cutting, CNC shearing , CNC bending, tapping and stamping machines. |

Test equipment | Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin guage,etc. |

Inspection | 1.)Analyzing the raw material before the production |

2.)Inspecting components during the production | |

3.)100% QC quality inspection before delivery, inspection report is available | |

Advantages | 1.) 24 hours online service & quickly quote |

2.) Sample could deliveried in 7 days | |

3) Competitive price, 20% lower than EU market. | |

4.) 10+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. | |

File Format | Pro/Engineer, AutoCAD(DXF, DWG), TIF, UG, Mastercam, 2D(PDF, DWG, DXF, CAD); 3D((IGS, X-T, STEP, STP) |

TOP® focuses on the field of precision manufacturing, providing customers with flexible and efficient smart manufacturing solutions,and its business covers Robot and Automation,Heavy machinery&Packing,Automative, Electronic& Semiconductor,Consumer ,Energy ,Medical andAerospace industry, etc.

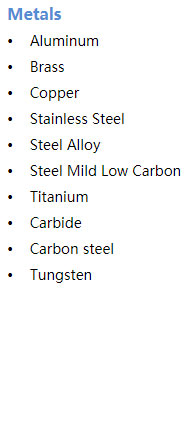

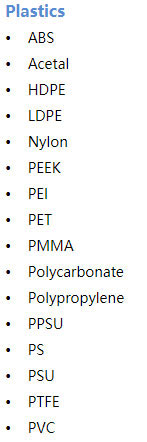

CNC Machining Materials

Explore Production

Why Choose TOP for CNC Machining?

●Fast & Reliable Delivery

Our CNC manufacturing network provides machined prototypes and production parts quickly and affordably with 100 workers and 60 cnc machines.

●High Quality CNC Machined Parts

More than 60 modern and comprehensive CNC machining centers, measuring instrument and three-dimensional inspection equipment. our quality management system is ISO 9001:2015 certified.

●Domestic Support

Professional fabrication engineers, average of more than 10 years experience in metal w machining industry. we ll help with ordering parts, design feedback, material recommendations, and answer any questions.

Custom CNC Machining Service

TOP provides you excellent custom CNC machining service. We have capabilities to help build your components to your exact expectation with our multi-axis milling services. If you have no idea which services is more suitable for your design, please feel free contact us, our experienced and skilled engineers will assist you for any of your questions to help you make the best decision.