Aerospace

What is Aerospace CNC Machining?

Aerospace CNC machining is special for creating of parts used in assembling and maintaining aircraft and space shuttles. CNC machined components, kits, and assemblies are often necessary for aircrafts in the aerospace industry. Such as hinges, bushings, manifolds, clamps, or other custom manufactured parts, aerospace equipment, and aircraft parts. All of these parts need the best components made with the highest quality metals in order to function properly. Titanium and Kovar are most often used for aerospace components, others material including stainless steel, Inconel, aluminum, brass, bronze, ceramic, copper, and some certain types of plastic also being used.

Material used in the aerospace

Stainless Steel Stainless steel is known for its high strength, good wear resistance, and low cost. The combination of these properties have made it a popular material in the aerospace & UAV industry.

Titanium

Titanium is a material of choice for aerospace applications because of its low density,lightweight, high tensile strength and outstanding corrosion resistance properties. Alloyed with aluminum and vanadium, titanium is used in aircraft for firewalls, outer skin, landing-gear components, hydraulic tubing, and engine supports. The compressor blades, disks, and housing of jet engines are also made of titanium. The space shuttle has many titanium parts as well as the international space station.

Aluminium

Aluminium’s high strength-to-weight ratio, stability, low risk of deformation have led to aluminum's broad adoption in the aerospace& UAV industry. In the aerospace industry, components ranging from antennas to fuel tanks consist of aluminum alloys. Contoured seats and instrument panels require the ductility and formability of aluminum 606. Structural supports, wing spars, wing skins, rods, or gears that endure higher mechanical stress levels and the temperature usually rely on the exceptional tensile and shear strength of aluminum 7075.

Teflon

Teflon, a popular engineering plastic, which is commonly used in aerospace & UAV industry due to its excellent mechanical p erformance, resistance to wear and temperature, low friction.

Given the critical nature of many aerospace and aviation applications, the components produced must meet or exceed high standards for precision, accuracy, durability, reliability, and quality. Otherwise, they may fail during an operation。

Our engineers meet and exceed industry standards, continually revolutionizing the machining process. Whether your aerospace parts require 5 axis CNC machining or wire EDM with exacting tolerances, our machinists have the knowledge, experience, and dedication to deliver the complex components you need with the highest precision possible.

We can provide precision machining for components throughout the aerospace industry. Applications include:

● Aircraft

● Aircraft testing equipment

● Missiles

● Rockets

● Spacecraft

● Defense

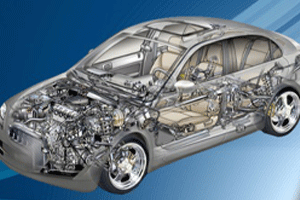

Complex Aircraft Parts Machined to the Highest Standards

We has experience with CNC machining for the aircraft industry. As air travel continues to build and expand, aircraft fleets consistently need the best parts to maintain efficient, reliable operation and safety. Precision and accuracy are of the utmost importance when machining components for civil aviation and military aviation needs.

Our skilled machinists work closely with clients to develop the specific aircraft components and spare parts your project requires.

Contact us for a Quote on your aerospace Parts.